Battery swapping enables rapid energy replenishment and has emerged as a key trend in the new energy sector. As a domestic pioneer in exploring battery swapping models for new energy vehicles, the company holds a leading position in the battery swap station industry, backed by extensive experience. It provides customers with safe, efficient, and reliable integrated solutions and services across multiple dimensions, including battery swap/charging stations for passenger and commercial vehicles, operational services, and maintenance management.

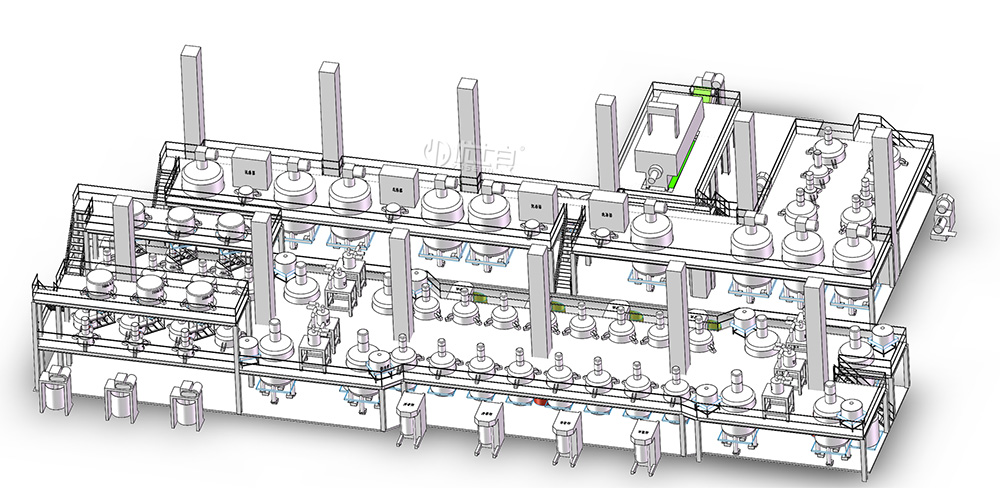

The intelligent production line for lithium battery slurry is highly efficient and energy-saving, significantly improving slurry quality and production efficiency. Through flexible modular design, it helps customers achieve rapid deployment and cost optimization.

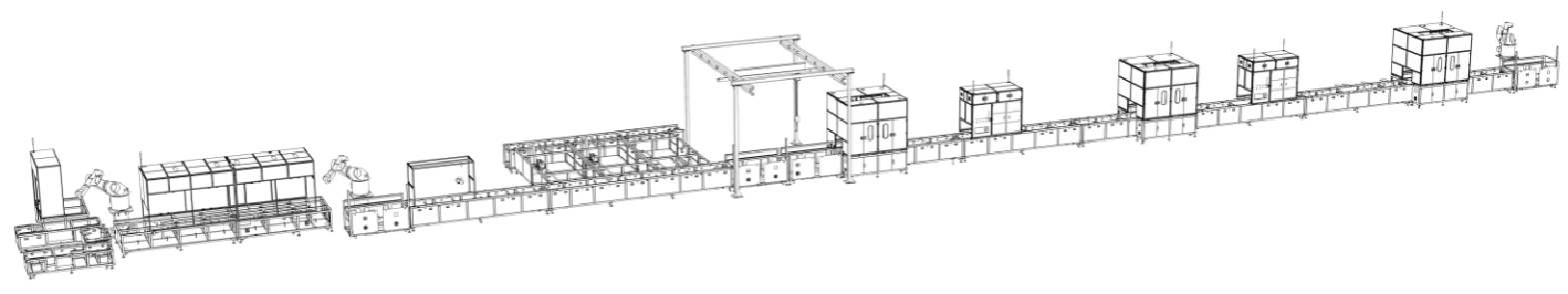

1. Full inspection of incoming cells for voltage, internal resistance, and thickness to ensure module consistency.

2. Modular design of the A/B-component adhesive dispensing and metering system, independently controlling and adjusting dispensing pressure and pre-pressure, with programmable mixing ratio adjustment and built-in flow monitoring function.

3. Standardized module stacking references ensure high consistency, enabling one-key switching of module recipes.

4. Fully automatic laser welding addressing and defocus detection, with unified fixture references to ensure high welding consistency, free from missing welds or false welds.

5. Proprietary airflow-based dust removal system to ensure no laser obstruction by fumes, and no dust or welding slag.

6. Compatible with different product series, featuring short model changeover time and low cost.